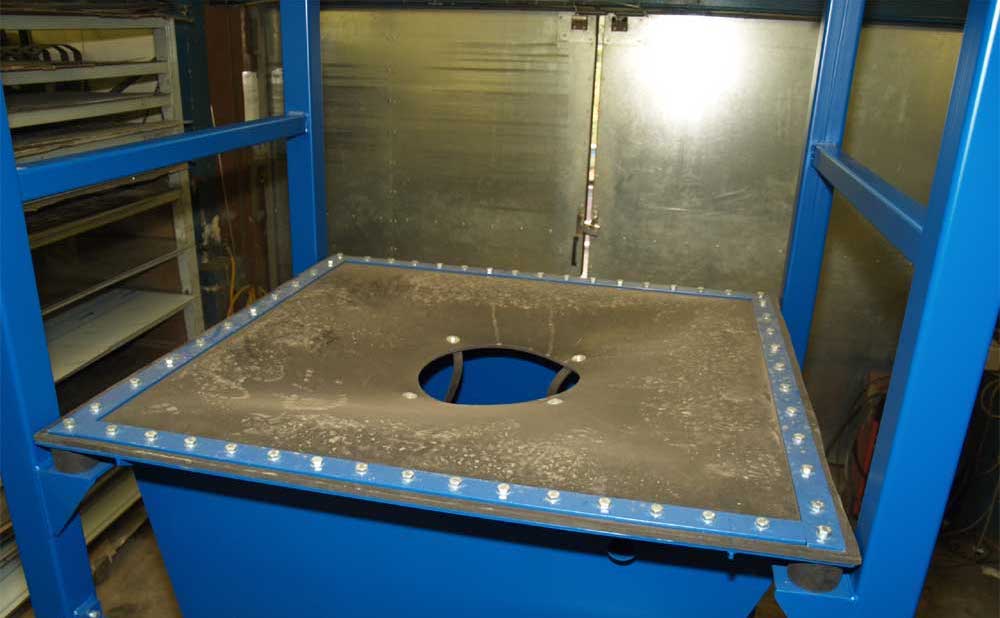

Using high quality, heavy duty materials and components with a powder coated finish, our unit is durable enough to withstand the rigours of industrial applications. Available as a fork lift truck loading unit, or a self loading unit with integrated crane, the bag is supported during emptying onto the large square rubber diaphragm.

The top frame is height adjustable to enable a range of bag sizes to be supported. The neck of the Big Bag then passes through into the lower chamber which is accessed through a large, lockable, sealed door.